RadCam/JMC Colour Chart and Image Processing

Externship summary

My KT project, named “RadCam Colour Chart and Image Processing” (RadCam CC/IPS), was conceived to develop colour correction and calibration capabilities for MCSE’s RadCam camera, which will be used for ESA’s JUpiter ICy moons Explorer (JUICE) monitoring cameras. These cameras will monitor the health of the spacecraft and its appendages during the various mission phases, and take spectacular, wide-angle, colour views of the Jupiter system during the mission.

In a typical digital colour camera, each pixel has either a red, blue or green filter, and standard, so-called demosaicing algorithms are used to find RGB values at each pixel so that a full colour image can be displayed. The RadCam has a custom Red-Green-Yellow-Blue pattern, so it required a calibration tool with colour standards in its field of view (FoV) to convert images to the standard RGB values. The main objectives of the project were therefore to design, manufacture, and space-qualify a colour calibration chart (CC) with colour standards; and to develop an image processing software (IPS) that would retrieve colour from the raw images using the CC, but also correct noise sources from the sensors.

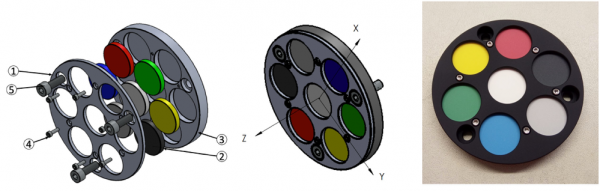

In addition to the design, manufacture, and space-qualification tests, work also included mechanical and thermal stress simulations, and ionising radiation experiments to test the performance of the colour standards. The design and a photo of the final colour chart delivered to ESA are seen in figure 1. The materials for the colour standards are aluminium silicate ceramics like those used for a colour chart on NASA’s Mars2020 rover, and the ionising radiation tests were performed in the Bern Inselspital cyclotron through a collaboration with the University of Bern. As a result of these studies, I am submitting abstracts to materials and planetary science conferences, and a paper is being prepared for peer-reviewed publication.

Figure 1: CAD (left) and photo (right) of the RadCam CC. The ceramic colour patches are 18.9 mm in diameter and 3 mm in thickness.

The IPS was developed concurrently with the CC and concluded a few months after CC delivery. Figure 2 shows a comparison between a raw JMC image, and one corrected by the IPS using the CC.

Figure 2. Left: Raw image taken by the RadCam/JMC PFM01 in the laboratory. The square patterns of the CFA are visible. Right: Final image after complete processing with the RadCam IPS.

Knowledge Transfer

My main contribution in terms of knowledge transferred to MCSE for this project was my experience in the use and conception of instruments for space missions, specifically my knowledge of the physics of spectral reflectance and of appropriate characterisation and calibration experiments. In addition, MCSE vastly benefited from my scientific network, as the collaborations that made this project possible were all founded on my prior academic collaborations with colleagues at the University of Bern, and external researchers at the University of Copenhagen.

In terms of knowledge transferred to me by MCSE, the transfer is also extensive. I have learned a huge amount about project management; product and quality assurance; space project requirements and verification; assembly, integration, and testing procedures; and resources and team management.

Overall, the project was a success. Though there were, of course, many delays and difficulties, I learned a vast amount of new information in a short time. After conclusion of the project, I was hired by MCSE as full-time Project Scientist and Manager. I believe this experience has been invaluable and will without a doubt help me in my future career.